Leica M9

Forward: This is a long missive, but the story is interesting and solves the mystery of the Leica 'corroded' image sensors.

The Leica M9 was manufactured from 2009 to 2014. Production estimates are around 180,000 camers. Leica made a variety of different versions including steel-gray paint, black paint, siver-chrome, Titanium, Vulcanite jacket and sapphire-crystal monitor, Hermes edition, purple shutter cameras (why?) and probably others. Leica likes to create lots of expensive variations of their cameras which leads to some wondering how much Leica is pandering to high networth individuals versus camera performance, but I suppose a company could hold both goals.

The M9 is a nice solid camera and for those who have not shot with a rangefinder, the experience is completely different than the 99% of point and shoot, mirrorless and DSLR cameras. With the typical camera, it is constantly trying to figure out optimum exposure, focus, ISO. The cameras have sophisticated Auto Focus (AF) systems including some that look at your eye to see where it is looking. The M9 rangefinder is completely different. You have to set focus. There is no AF. You look through the rangefinder, and focus the lens by aligning a split focus screen. The lenses are beefy, metal things with various grooved and turned rings to that you can feel what you are adjusting.

When you are ready to take a picture, you turn on the camera, set your focus (you can also set focus with the camera off) and aperture, and click. You hear a variety of sounds that seem like an film camera. And you watch a blinking light flash - for about 7 seconds - while the camera writes to the memory card. Depending, the camera has a 7-8 shot memory buffer. After that, wait 7 seconds before you can take another picture. You have to start thinking carefully before you press the shutter. Want to take a picture of you kid blowing out a birthday candle? Better get that timing right because your next shot will be them eating cake. Now this is a good and bad thing. On one hand, you have to think about your shot before you take it. On the other hand, sometimes catching the exact specific moment is hard. Maybe they could have compromised and give you a bigger memory buffer. Just my opinion, but the memory chips are inexpensive, and this is a camera that sold for $8,000.00 USD.

The real Leica cameras (not the rebadged Panansonic ones) are built like tanks, We are talking old time, heavy duty, German engineering where there is one right way. Solid camera, solid lens with great optics, and force user engagement.

The M9 used a 18MP Kodak full frame CCD sensor. Kodak sold their image sensor business to Truesense which was owned by Platinum Equity in 2011. Platinum Equity flipped the business to On Semi in 2014. Many of the old Kodak medium format cameras I have opened used the IR Cut Filter (ICF) as the sensor coverglass as well. Typically, the ICF is a separate peice of glass held in front of the clear sensor coverglass. I don't know if Kodak did that to lower costs or perhaps increase optical performance since every piece of glass light has to go through degrades the image somewhat.

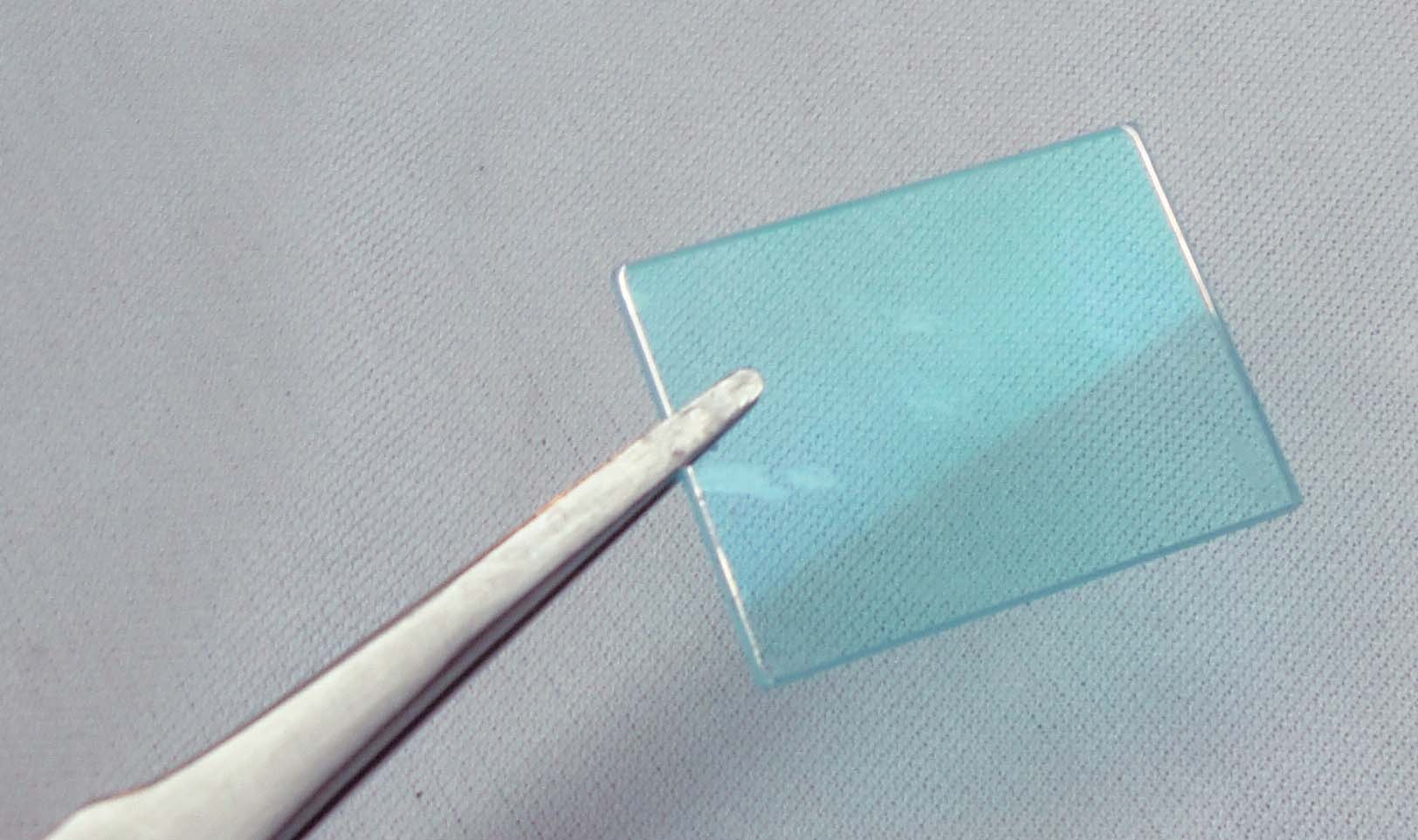

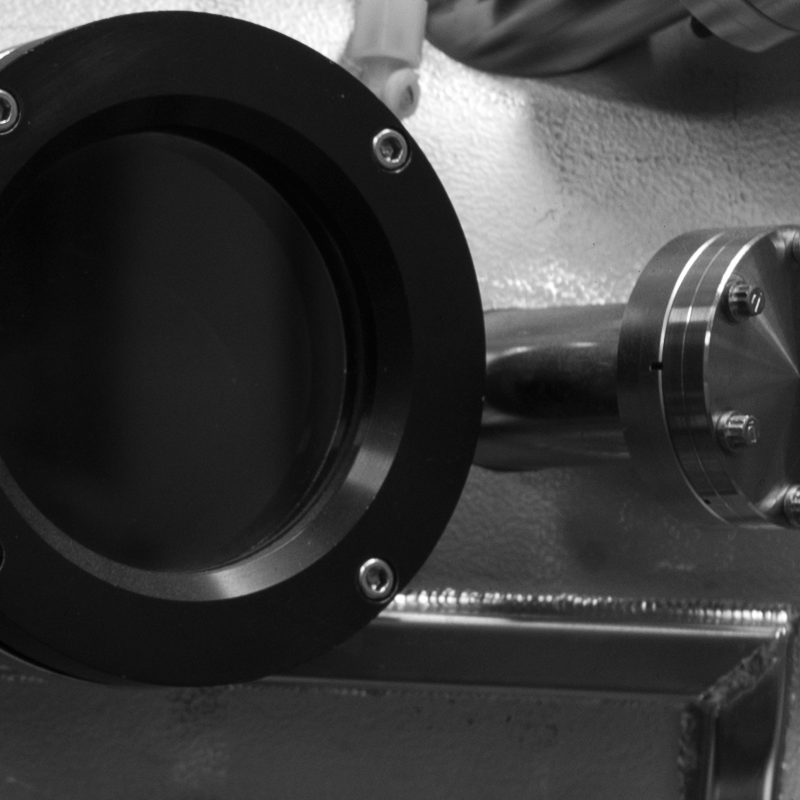

Here is a typical ICF. This one has three layers. The IR absorbing glass (the teal color) which has vapor deposition coatings to further shape the response and 2 layers of clear lithium niobate which make the AA/OLPF/Blur filter (horizontal and vertical blur).

It used to be that if you scratched the ICF, you could send the camera in, and they would replace just the ICF leaving the original sensor in the camera. Now, perhaps because of the higher resolutions and the difficulty of getting the glass really clean, the manufacturers force you to buy a new sensor with the ICF already attached.

There are a few shops such as ours that can replace a damaged ICF. There is no shop, except ours, that buys custom glass for each type of camera. Thickness is critical if you don't want to change focal plane. But buying lots of custom glass is expensive. Instead others use a few standard pieces of glass and then, if they even do that, adjust the sensor position to compensate for the focal plane change. I have seen hardware washers used as shims, belt sanded sanded sensor mounting points and such silly stuff that I won't work on a camera that has been modified and lost its factory sensor mounting position. It is too much work to correct.

When we put in our Class 100 clean bench in 2005, another prominent shop announced they had the same type of bench as well. Buyer beware. For our monochrome conversions, When our customer used our monochrome camera to make the youtube video, 'How the sun sees you' (18,639,712 hits so far), a well known shop put the video on their website implying that they could make monochrome conversion (they can't). While we don't have the flashiest website, there is no shop in the world offering the breath of our camera conversions, optical filters, lights, phosphors, inks and knowledge, with the equipment to back it up. Our goal is not to be the least expensive. Competeing on price leads to a race to the bottoms. We compete on quality, and no shop can match our quality. And we aren't that more expensive anyhow.

As an aside, back in 2005, we had a customer that upgraded their Nikon D70 for a D200 and noticed that the images were softer on the D200. The ICF is typically a combination of IR absorbing glass, various coatings and layers of lithium niobate which makes for the camera's Anti Aliasing/Optical Low Pass Filter/Blur Filter. Lithium niobate splits light into two polarizations. The thickness of the filter determines the amount of the the split. There are two layers - vertical and horizontal splits. The D70 had a thinner ICF/AA stack (1.30mm) than the D200 (2.15mm) by quite a bit. The customer asked me to install the D70 ICF in his D200 and images became noticeably sharper. For some odd reason, Nikon decided to add more blur to the D200 when, logically, with a smaller pixel size, you need less blur. At that point, I decided to get custom ICF's made to replace various camera ICF/AA stacks where the new ICF had the exact same thickness as the old stack so that the focal plane didn't change. We called that our High Resolution (HR) conversion. My guess is manufacturers worried that a reviewer would show how the camera would alias at the limit of their resolution on certain repeating patterns where the pattern was almost the same as the pixel spacing and declare the camera was defective. However, the flip side is that you give up on resolution when you have an AA filter, and those problems rarely occur anyhow. No medium format camera has an AA filter because the guys paying big money for those cameras wouldn't put up with it. As the years have gone on, manufacturers are increasingly making cameras with no AA filter, and I suspect we are a big factor.

I was curious about what this Leica 'sensor corrosion' actually was. I haven't seen the actual surface of the sensor corrode, and my guess was that something was happening to the ICF. Because Kodak liked to epoxy the ICF to the ceramic chip as the coverglass, maybe Leica couldn't just change the ICF. One theory I thought of was that perhaps there where pinholes in the vapor deposition metallic coatings that are applied to the ICF. Maybe those pinholes where oxidizing over time, but that is still a curious thing because coatings don't do that (at least I haven't seen it).

At first, Leica would replace the bad sensors at no charge - though sometimes it would take 6 months for customers to get their cameras back. Later, Leica started charging $1,600 to replace the sensor. Then On Semi, the company that made those sensors, decided to exit the CCD business. Now Leica, and their customers, are in a real jam because if their sensor goes bad, the camera becomes a brick. Leica is giving customers with a bad camera a credit towards a new camera, so, to their credit, they are trying to do the right thing.

I looked around a bit a found a M9 that was in really good shape except that the sensor was in horrible shape. Completely unusable.

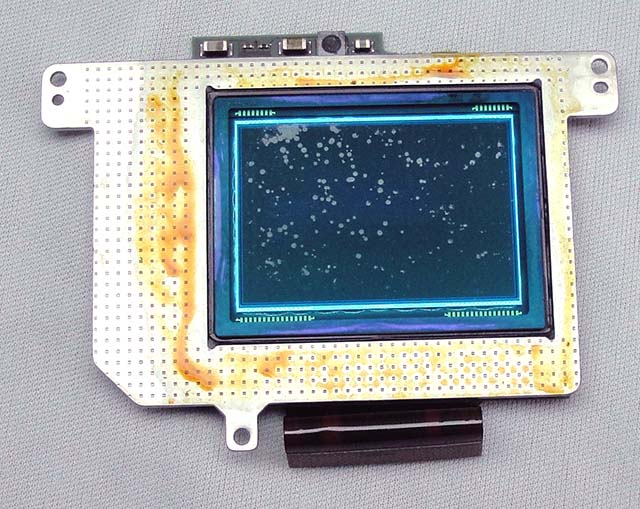

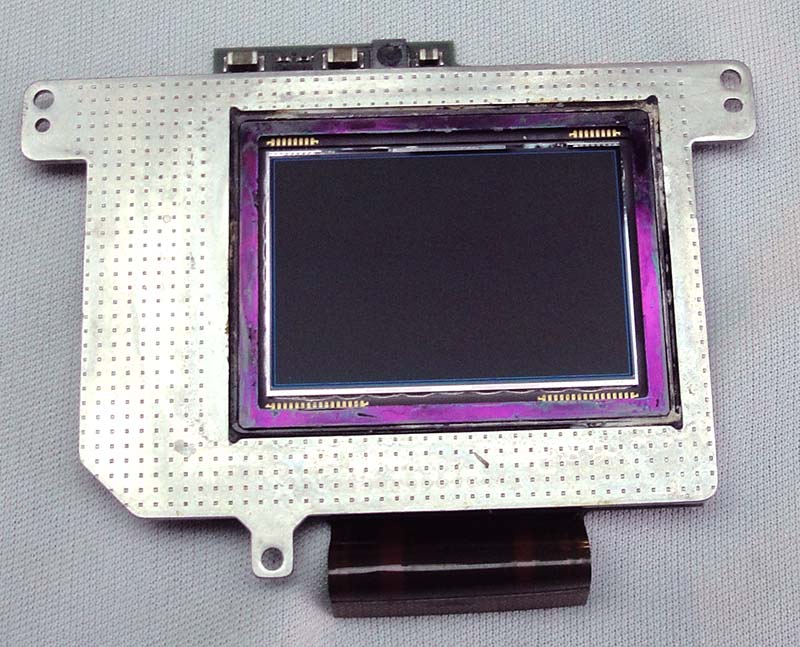

Taking the camera apart, here is what the sensor looks like out of the camera. That brown stuff around the sensor is from something that someone did while trying to clean the sensor.

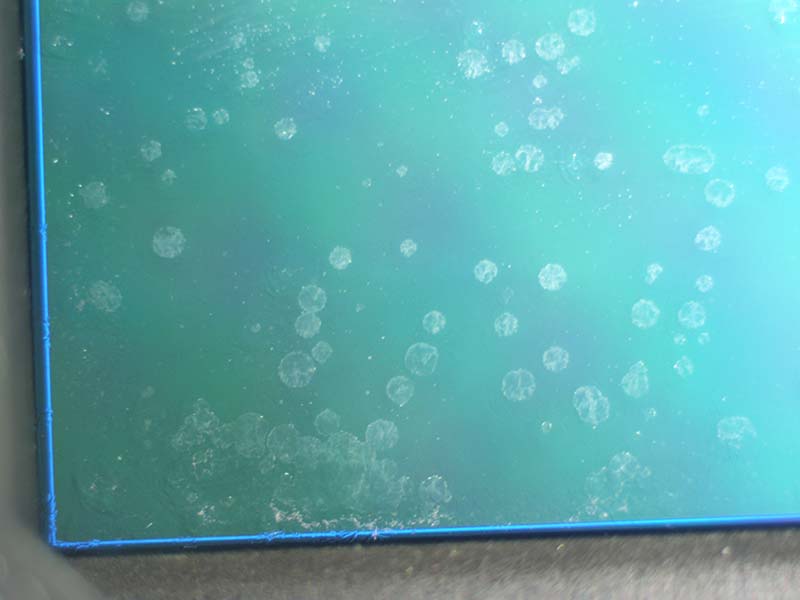

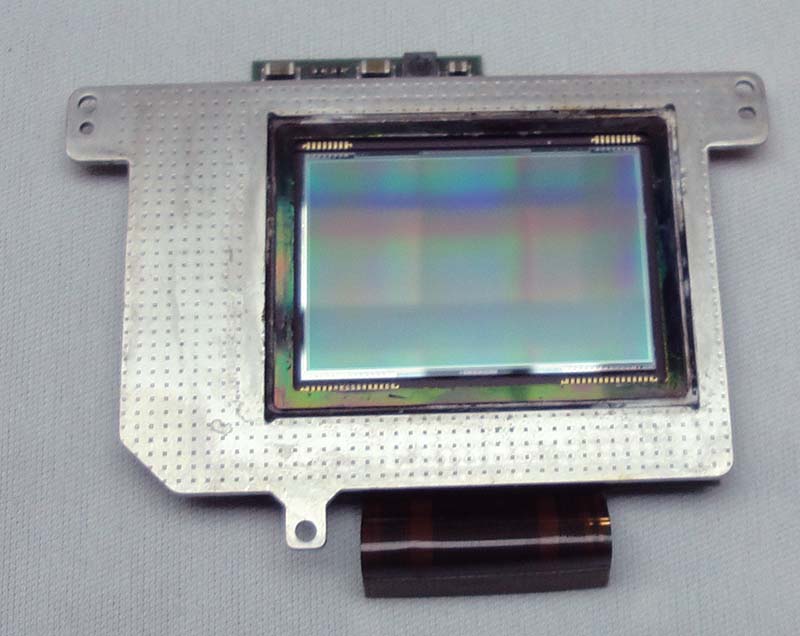

Here is what the sensor looks like under a microscope.

You can see that the problem is something has gone wrong with the ICF, and that ICF is indeed epoxied to the ceramic package as the coverglass. My next thought was I wondered what would happen if I polished the ICF using synthetic sapphire 1 micron polish. I polished most of the corrosion off and took another look at the ICF and found that the surface of the glass itself pits from the oxidization! That's something I haven't seen before. Very odd. The sensor is no good with suface defects like that.

Next, time to take the sensor coverglass off which is a rather delicate operation. There are 5 micron gold bonding wire a millimeter or so under the glass that connect the active chip to the electrical connectors outside the sensor. If you touch the gold wire and break it, you need a special wire bonding machine. We have one, but I haven't become proficient enough at using (story for another day). You can't touch the surface of the sensor, or you leave permanent damage.

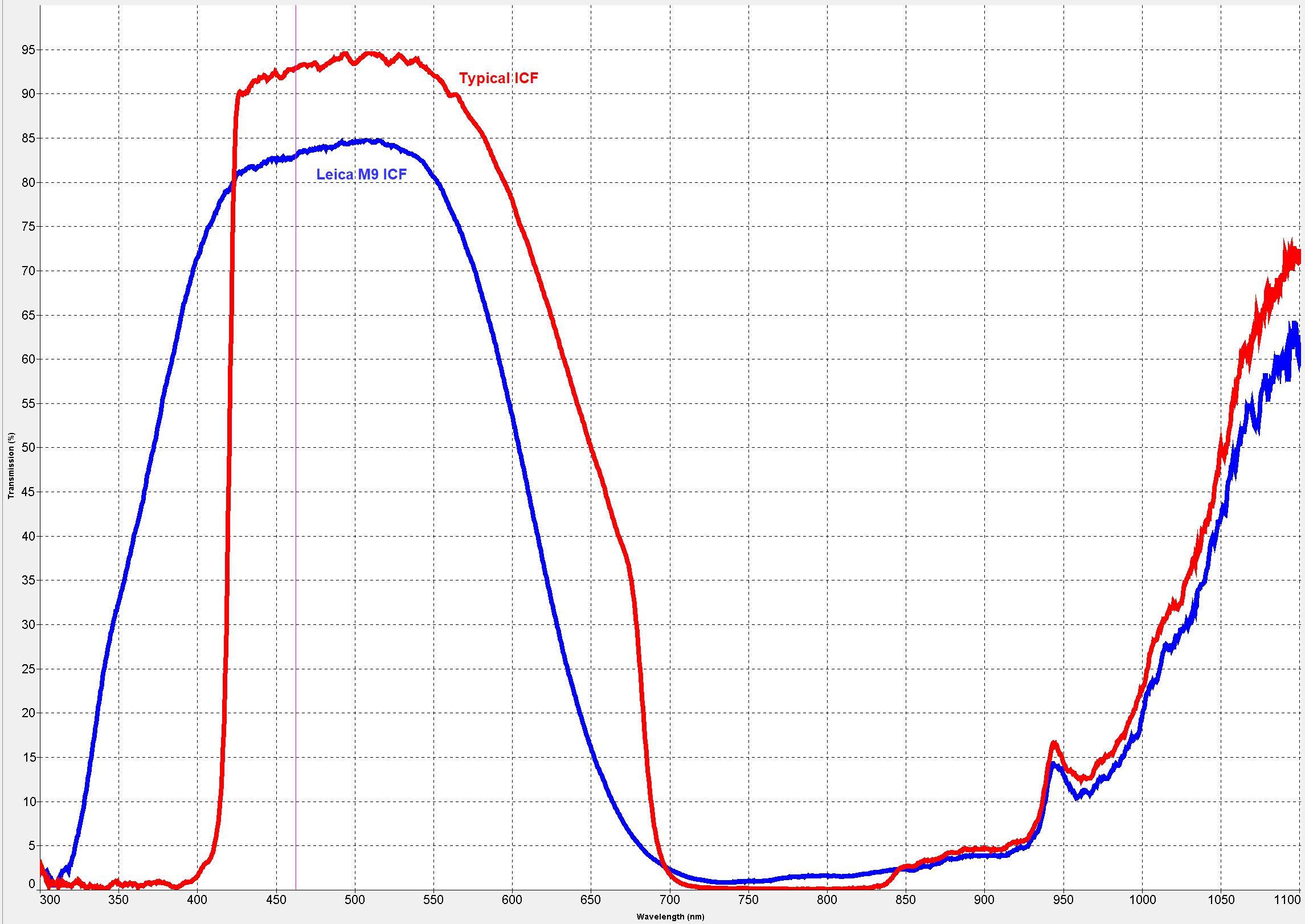

After taking the ICF/Coverglass off, I measured the ICF with one of our spectrometers. What I found was a filter that extended down to 300nm. That filter doesn't have coatings! Notice in the graph below how the typical ICF has a sharp cutoff around 420nm. That is because of those metallic coatings I mentioned earlier. Leica / Kodak used an uncoated Schott BG type glass! The coatings seal the glass. Somebody *really* screwed up. All those BG and UG types of glasses are susceptible to oxidization. Variable include time, temperature, humidity, ozone and even the particular glass melt, but you would never put uncoated BG or UG glass in a camera and not think that one day you are going to have a problem. That Leica / Kodak would do that boggles the mind.

Another really odd thing is that they used a filter that passes light down to 300nm. For a consumer camera, I have never seen that. Camera sensitivity below 400nm is pretty low, but, still, it is just really strange to see a customer color camera with a filter like that - like I have never seen that ever in 25 years.

This also solves the mystery of the Leica 'sensor corrosion'. Not 'corrosion'; that's oxidization cause by a lack of protective coatings. Stupid, stupid, stupid. Now maybe they later started adding coatings that later became defective, but at least for my camera (with the serial number hand written inside of 66,643), the defect was caused by using unprotected glass.

This graph shows the filter transmission response curve of the M9 ICF versus almost every other ICF. Generally, the manufacturer's ICF is designed to pass light form 420nm (blue light) to 650-700nm (red light). Our human eyes can see above and below that but sensitivity is low. My upper limit is around 910nm.

Here is what a 1/4 block of BG38 (our XNiteCC1 filter) looks like after coming out of the melt.

As long as we had the sensor coverglass off, we figured, why not remove the Color Filter Array (CFA) and turn it into a monochrome camera. We can make the cameras transition from a useless brick to a Monochrom M.

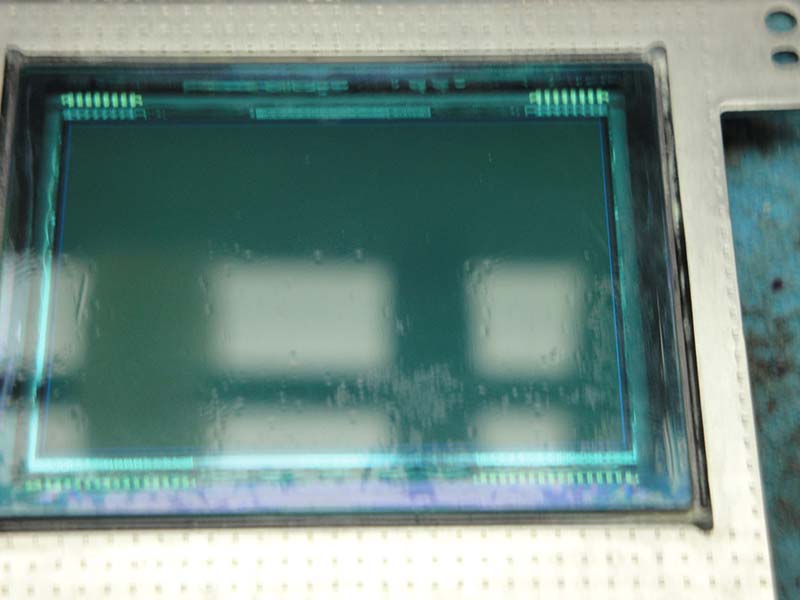

Sensor out, coverglass removed and cleaned up.

Sensor out, CFA removed. Now the sensor is monochrome. Notice the edge to edge precise CFA removal.

Here is a quick look at some images. These were shot with a fairly inexpensive ($450) TTArtisan 35mm F1.4 lens.

100% Crop

100% Crop

100% Crop

Here is a comparison of a color and monochrome M9 both using the same Voigtlander Nokton 50mm F/1.5 lens at F8 aperture.

Color Camera

Monochrome Camera

Comparison

What are the costs to do this?

We can offer the following conversion options:

1: Replace the defective ICF with a new ICF leaving the camera as a color camera: $1,500

2: Replace the defective ICF with a UV-VIS-IR window making the camera into a full spectrum color camera: $1,500.

Note that with this conversion, you will generally want to use a filter on your lens. For visible light pictures, you would use our UV and IR blocking XNiteCC1 filter. If you wanted to take an IR picture, you could use a variety of IR longpass and bandpass filters. If you wanted to take a UV picture, you would use a UV shortpass filter. We have hundreds of filter options in diameters from 25mm to 82mm.

3: Replace the defective ICF with a new ICF and change the sensor to monochrome: $2,500

4: Replace the defective ICF with a UV-VIS-IR windows making the camera into a full spectrum monochrome camera : $2,500.

UV sensitivity will be about 6x greater than leaving the camera as a color camera. Again, you would generally be using filters on your lens depending on what type of light you want the camera to see.