Shutter LED Problem

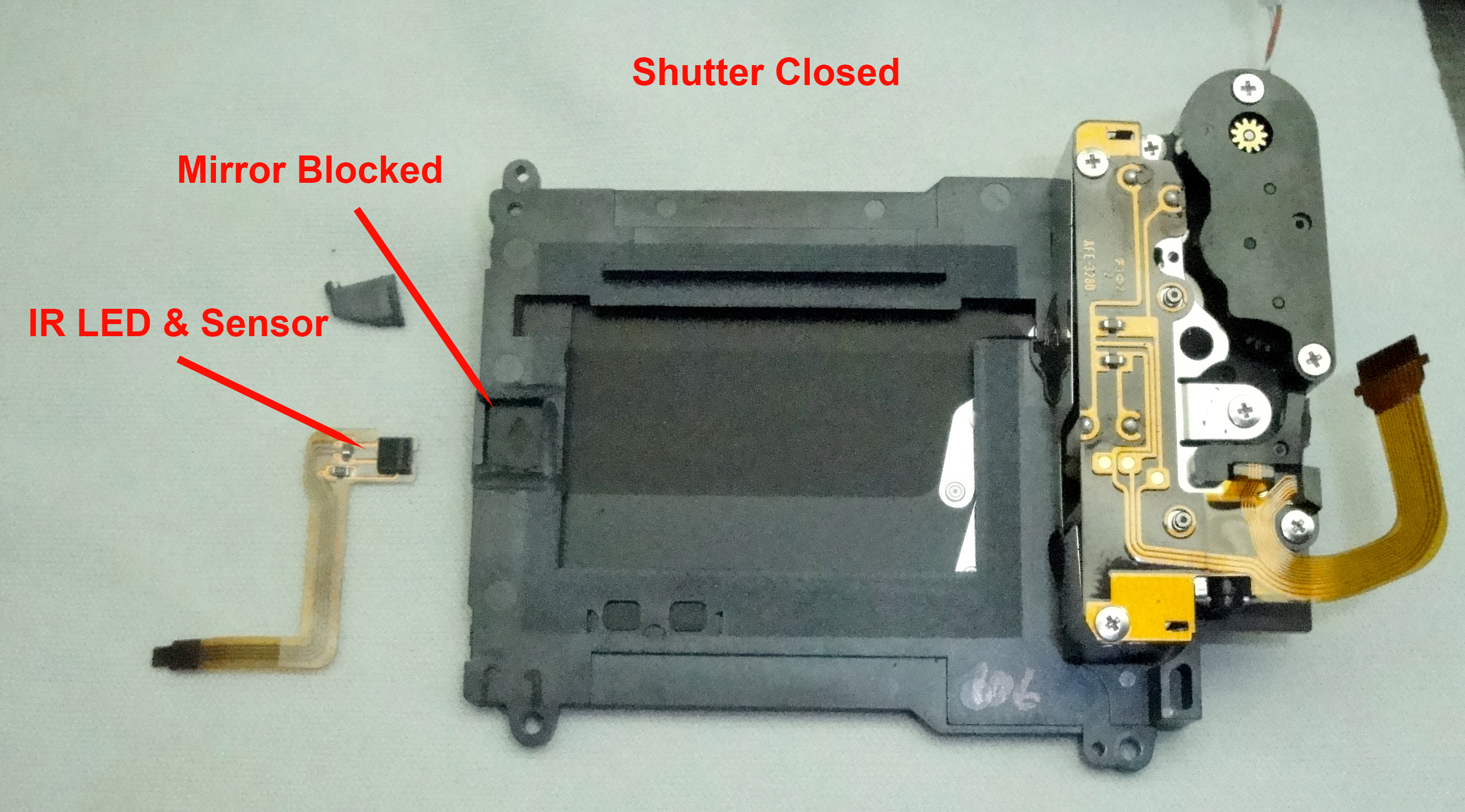

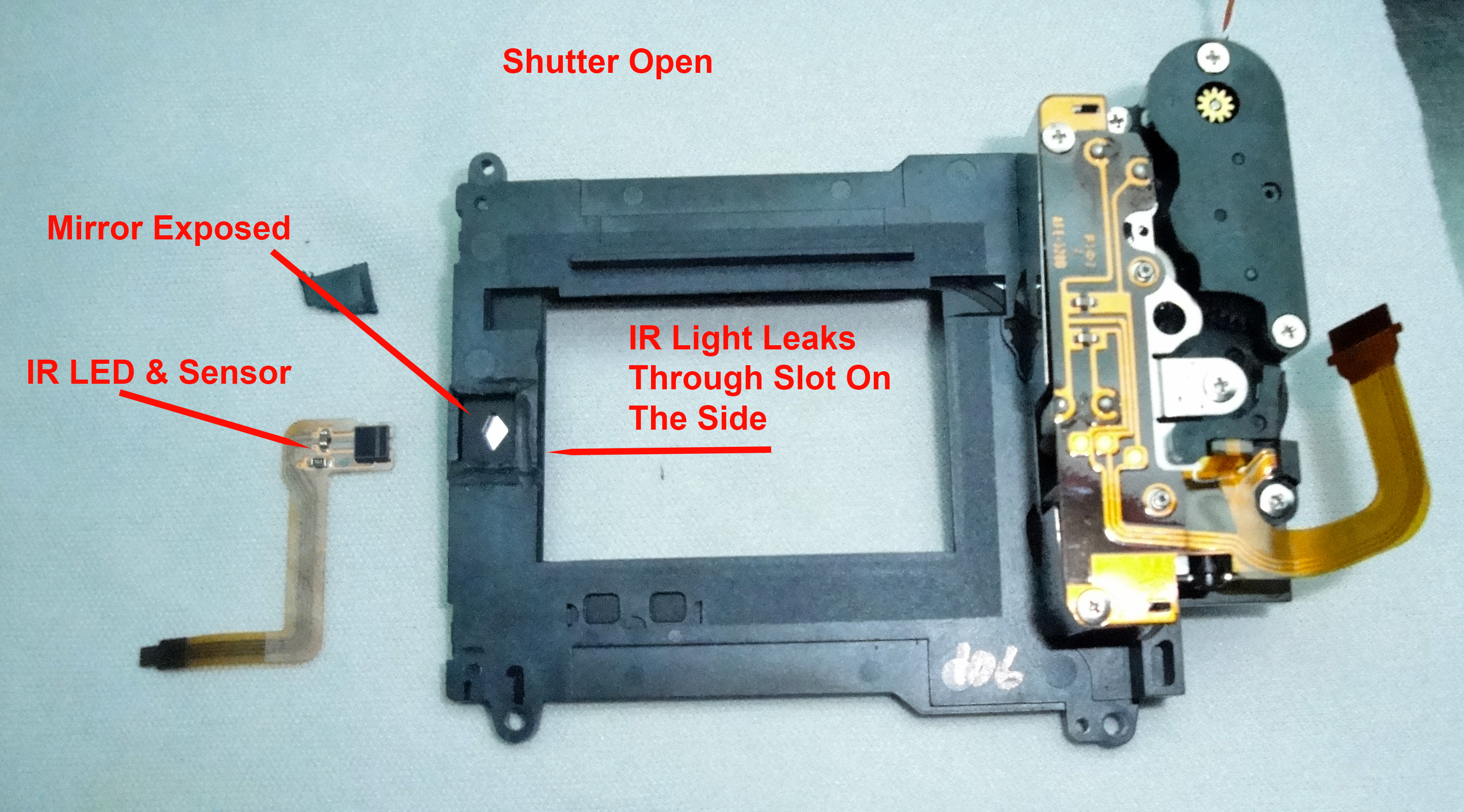

On some cameras, the manufacturers have an IR LED to monitor if the shutter is opening and closing correctly. The IR LED shines through a hole in the shutter where the blades block a mirror when the shutter is closed. When the shutter is open, the IR light bounces off the exposed mirror and back to the sensor assembly where the light is detected. While the LED is on and when the shutter is opened, there is a gap on the side where the shutter blades slide up and down. This results in some IR light escaping past the track where it can bounce around inside the camera eventually hitting the sensor.

Normally, this is not a problem because color digital cameras have an IR Cut Filter (ICF) which blocks IR light. But on cameras modified to see in the IR, the light can result in a fogging of the image which usually happens on one side of the sensor and is generally only noticeable on high ISO / long shutter exposures. The most common IR LED used for the sensor is an 850nm type. Curiously, there are some cameras that use a 940nm IR LED which largely eliminates the problem because the image sensor has much lower sensitivity at 940nm.

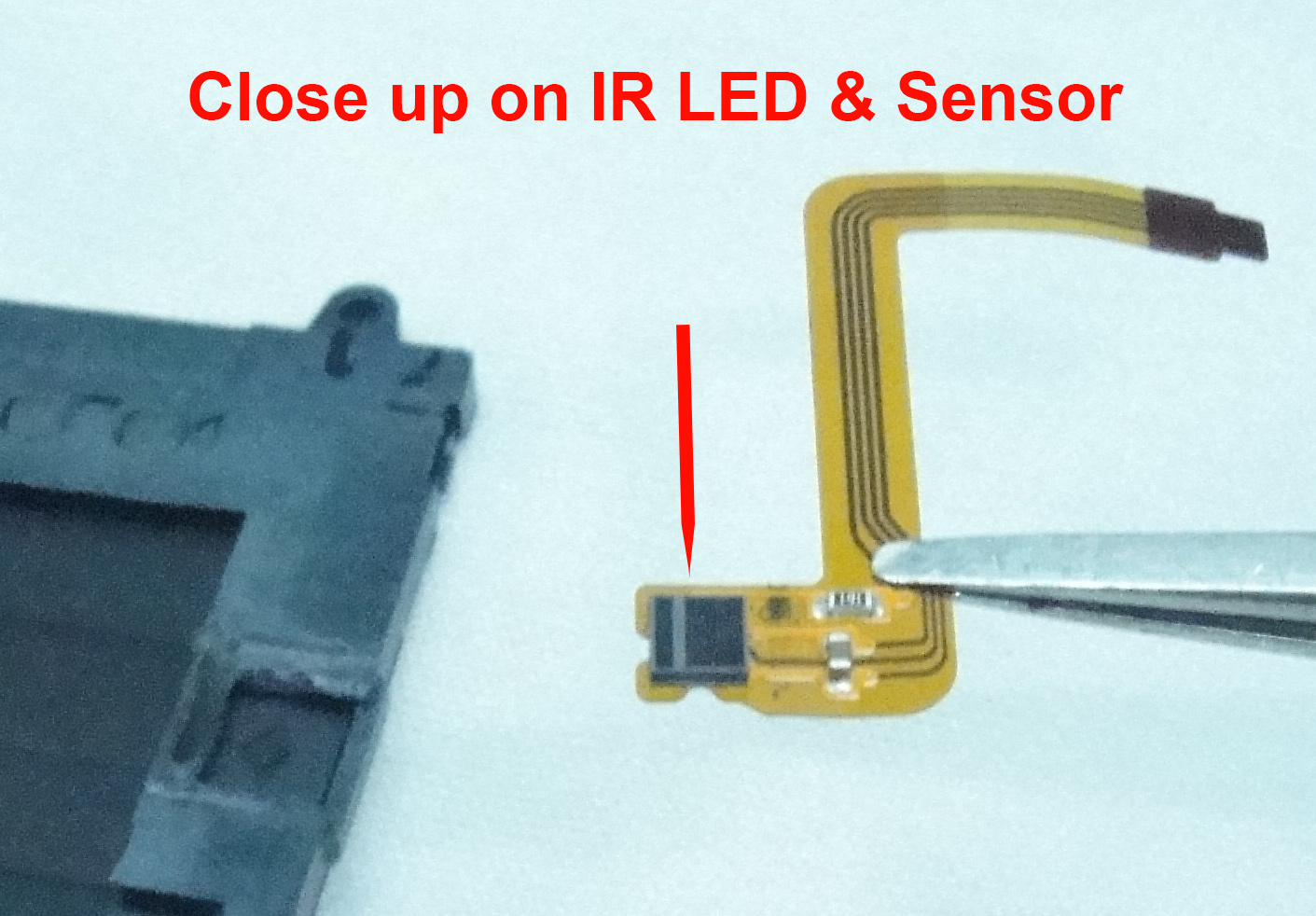

Perhaps a fix would be to change the IR LED from an 850nm to 940nm, but as you can see, the LED and sensor are SMT mounted on flex cable making modification difficult for the casual enthusiast.

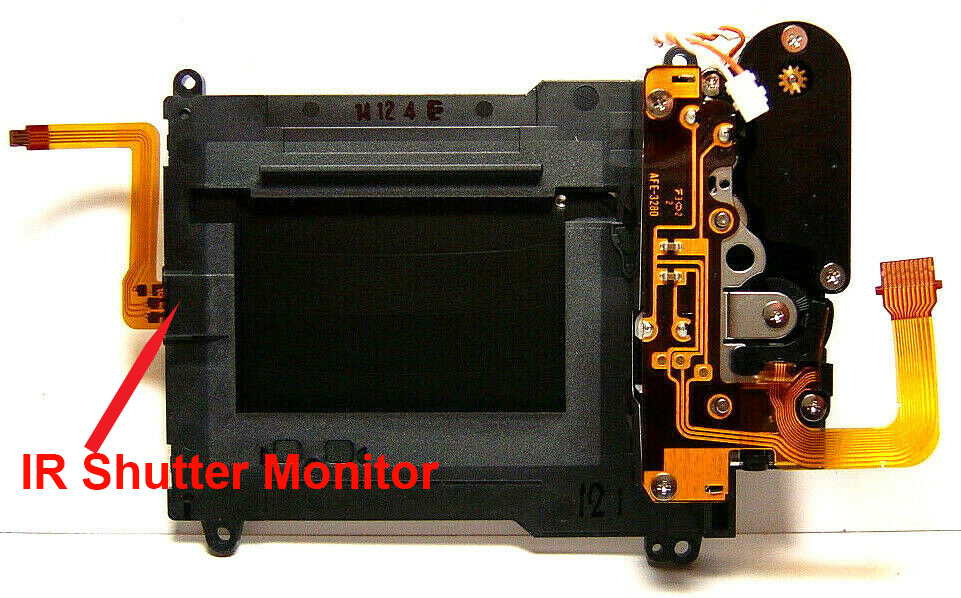

Nikon D750 Shutter Assembly

The IR shutter monitor is inside the black plastic

Here we removed the shutter sensor assembly and cut off the top of the plastic covering the sensor LED.

The problem part.