Hall Of Shame

We tend not to discuss much about others that convert cameras. We have seen enough over the years to warrant educating people though.

Converting cameras is a precision business. You must know what you are doing, know how to work on electronics and utilize special techniques and equipment for a clean conversion. With the high resolutions of today's cameras, you can't work on a camera yourself on a kitchen table. Besides the risk of damaging your camera, it is impossible to convert a dust free camera this way. Microscopic dust particles become tightly bound to glass by electrostatic forces. As particles become small, the electrostatic forces become very large. These small particles that are visible under a microscope cannot be cleaned with swabs, wipes or wet cleaning. These small particles will become spots, especially at small F-stops.

We work on cameras in a Class 100 clean bench environment. Class 100 US FED Std 209E is equivalent to a Class 5 ISO 14644-1. Class 100 environment means that maximum particles for cubic foot is 100 > 5 microns. Once we noted on our website that we installed a class 100 clean bench, one of our competitors claimed they had a ISO Class 100 clean bench a week later. Subsequently, they changed their claim to a Class 5 environment. We also don't claim to have equipment we don't really have.

We are not wedding photographers who convert cameras as a side job. We do not sell services to teach people how to retouch photographs. We sell and modify a wide variety of optical equipment. We have been in business since 1997 and occupy our own 6,500 square foot building. We ship worldwide on a daily basis and count many industrial, educational, scientific and military users as our customers.

We are not a camera repair shop. Converting a camera is a different business than repairing a camera. We specialize in converting cameras. We convert the widest variety of cameras and have the widest variety of types of conversions. We are not the most expensive nor the least expensive. We are the best and have been in business the longest.

We have a typical 1 to 2 day turn around. We don't sit on cameras for a month. We don't return someone else's camera body to you. You can send cameras in for conversion or buy a factory, brand new modified camera from us.

We don't sell kits for conversion. We think it is irresponsible to do so. Besides the impossibility of performing a clean conversion without special tools, equipment and techniques, the possibility of you damaging your camera is too great.

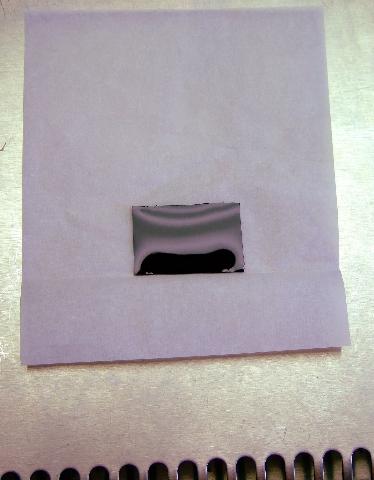

Here is an example of a camera that was sent to another business on the east coast for conversion. The customer was unhappy with the focus and dust particles. The conversion took 6 weeks. The IR filter used inside the camera was a piece of infrared plastic.

There are a few problems with using a piece of thin, wavy plastic over your sensor:

- The plastic is not as clear as glass. We use only glass from Germany.

- The plastic is wavy. The focal plane will change because the plastic is not flat!

- The plastic will scratch easily.

- The plastic will scratch easily

- The plastic thickness meant that the customer had to shoot at F11 or higher to achieve focus. The focal plane was completely incorrect.

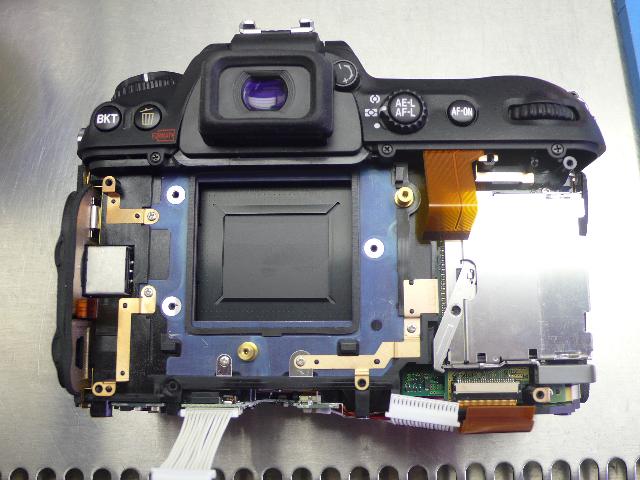

Here is another example for a customer who sent his Nikon D200 camera in to a shop of the west coast. Again, the conversion took over 6 weeks. The first time, the customer received back a body with the different serial number than the one he originally sent. The customer asked for an 830nm conversion. Later the customer asked us to convert the camera to 715nm because he didn't like the 830nm conversion, and he no longer trusted the shop. When we opened the camera, we found that the shop didn't have the correct thickness IR glass for conversion. Because the glass they had was too thick, they sanded (!) the sensor pads with a belt sander to move the sensor closer to the front of the camera. The sensor pads are precision machined surfaces that mate to machined surfaces on the camera body. The belt sander technique resulted in different pad heights and made the sensor no longer 100% parallel. If you look closely at the sanded pads, you can see the problem.

![]()

![]()

This is what a D200 sensor from the factory looks like.

The sensor mounts to machined surfaces visible here.

Please be careful to whom you entrust your camera. We have seen damaged cameras. We have seen cameras missing screws, missing internal parts like RF shields. We have heard countless stories about cameras taking a long time for conversion. We have heard of arrogant shops that attempt to bamboozle the customer with nonsense.

There are many steps to performing a quality conversion including quality glass, inspections, cleaning, assembly, testing, environmental and ability. Some shops will make claims that are false. For instance, when we installed a class 100 clean bench, a week later one of our competitors claimed the same thing. We have many steps in our conversions that we don't disclose because we don't need to educate our competitors, but our conversions are recognized to be the highest quality anywhere. Some of our conversions such as our ability to remove the Color Filter Array (CFA) from the surface of the camera aren't done by anyone else.

Do some research. We are not the cheapest nor the most expensive. We are the best in quality.